Principles

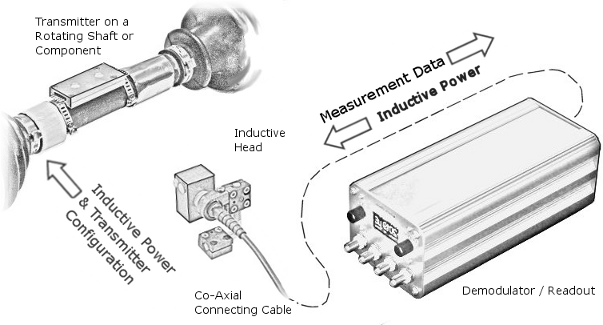

On the standard system range Astech Rotary Telemetry utilises inductive coupling to transfer both power and data across the air-gap between a shaft mounted sensor transmitter and a stationary head or loop. Strain, temperature etc sensors mounted on the rotating part are connected to a small transmitter module which provides signal conditioning and converts the measurement data into pulse code modulation (PCM) – a form of digital encoding well suited to rotary telemetry application and providing excellent data quality, in fact Astech pioneered the application of PCM to rotary telemetry in 1977. The PCM data then modulates a new power magnetic field and this field provides the means of transferring the measurement data to a demodulator unit.

A second magnetic field, generated by the inductive head, is used to transfer power to a loop or pickup mounted on the shaft, providing a non-contacting power supply to the transmitter.

Air-Gap for inductive power transfer is limited to approximately 50mm. By utilising a battery power supply the air-gap range can be extended to typically 150mm. Astech also manufacture longer range systems, in which radio takes the place of inductive coupling. Such systems have a range of 10 – 200metres, so are not generally required in rotary telemetry applications.